The Essential Design Process Before Starting Watch Manufacturing

When planning a original watch project, many clients ask, “What kind of design materials do I need to provide?”

Understanding the correct formats is crucial for a smooth manufacturing process. In this guide, we break down exactly how to prepare your watch designs for the manufacturer.

The Three Types of Design Materials

Watch design typically involves three stages of visualization: Rough Sketches, 2D Technical Drawings, and 3D CAD Data. While their levels of detail differ, each is essential for ensuring the manufacturer accurately understands your requirements. Below, we explain the specific role and purpose of each format.

Rough Sketch

(Handwriting acceptable)

Intended to communicate the general geometry and atmosphere. A high level of completion is not required; rough line work is acceptable.

2D Design Data

(Flat Design)

While the rough sketch is the initial phase of giving form to an idea, the 2D design data ensures the concept is universally communicable and understandable to all parties.

3D Data

This process involves engineering and verifying the internal structure, component mating (fitting), and overall manufacturing feasibility.

What specific details should be communicated to the manufacturer?

Watches are comprised of dozens to hundreds of precision components. Manufacturers will carefully assess your specifications—such as case profile, dial layout, hand style, and band construction—to translate your requirements into a tangible, optimized design.

| Component Name | Specification Items | Reference / Instructions |

| Case Shape | Examples: Round, Square, Tonneau, Cushion | ・Round ・CaseStandard 4-Lug Design |

| Case Profile / Thickness (Side View) | Define the position of the bezel, crown, and case back when viewed from the side. Note: Case thickness varies depending on the installed movement. | • Bezel Thickness: [ ] mm • Middle Case Thickness: [ ] mm • Case Back Thickness: [ ] mm • Total Thickness: [ ] mm |

| Dial Layout | Examples: Bar indices, Arabic numerals, Logo at 12 o’clock, Dial color/texture | • Dial: Black with Sunray finish • Indices: Stamped/Embossed Arabic numerals to create depth (3D effect). |

| Hand Design | Examples: Baton, Dauphine, Leaf, Pencil | • Specify the shape of the hands. • Specify the length of the hands. *Length is measured from the center axis (canon pinion) to the tip. |

| Lug Shape / Band Connection | Examples: Straight, Curved, Lug-less (Integrated) | Specify the design of the connection between the case and the band. (This should coordinate with the case shape). |

| Buckle Shape | Examples: Pin Buckle (Tang), Deployant Buckle, Butterfly Clasp | Specify the design of the fastening mechanism. |

| Strap Material | Examples: Calf Leather (Black), Croc-embossed (Brown) | Specify material, presence of stitching, and strap thickness. |

| Other Requirements | Examples: Logo engraving on crown, Exhibition case back, Water resistance rating | • Crown engraving: (Yes/No) • Case back engraving/design instructions • Water Resistance specification (e.g., 3ATM, 5ATM) • Glass material specification (e.g., Sapphire, Mineral) |

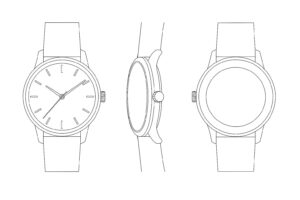

Design Specification Sheet (Reference Example)

This template provides a line drawing (wireframe) outlining the basic structure of the 3-view drawing (Front, Side, and Back) required for watch design. It serves as a base for rough sketches and specification reviews. A 3-view drawing must be created according to the specific case shape.

What does submitting a design to the manufacturer clarify?

In watch OEM manufacturing, “submitting the design” marks the starting point of the project.

Based on the submitted design data, the manufacturer evaluates manufacturing feasibility, structural engineering, costs, and the schedule.

Providing a design clarifies the following critical information:

- Case Unit Price

- Dial & Hands Costs

- Assembly Costs

- MOQ (Minimum Order Quantity)

- Total Estimated Quotation

The more precise the design, the smaller the margin of error in the quotation.

Conversely, vague designs result in a wider price range, making project decisions (budget allocation) difficult.

We will provide an estimated schedule calculated backward from the required processes. Key factors include:

- Tooling Requirements: Is a new mold required for the case?

- Dial Complexity: Number of print layers, luminous application (Lume), applied indices, etc.

- Outsourcing: Does the band require an external supplier?

- Prototyping: How many rounds of prototyping are necessary?

Manufacturing Schedule & Process

| Phase | Estimated Lead Time |

| Design Finalization | Approx. 1 – 2 Weeks |

| Prototyping (Sample Production) | Approx. 60 Days |

| Mass Production | Approx. 60 – 90 Days |

| Total Lead Time | Approx. 4 – 6 Months |

*Lead times will be extended for complex complications or jewelry watches.

*Time required for technical drawing creation is not included in the above estimates.

We can determine:

- Whether the design is physically manufacturable.

- Areas requiring modification or engineering adjustments.

- Alternative solutions for cost reduction.

- Technical risks (e.g., ensuring water resistance integrity).

Based on your design, we provide technical recommendations to enhance quality:

- Case: Changing from 316L Stainless Steel to Titanium for weight reduction.

- Glass: Upgrading from Mineral Glass to Sapphire Crystal.

- Strap: Adjusting leather thickness to improve durability.

- Case Back: Option for skeletonization (Exhibition Case Back).

We offer strategic advice ensuring the product matches your target market:

- “For a women’s model, this case diameter may be too large.”

- “For a sports model, we recommend increasing the water resistance rating.”

- “To lower the retail price, we suggest modifying the shape of the hands.”

Summary: The Importance of Watch Design

In watchmaking, “design” is not merely about aesthetics; it is a critical process that directly impacts manufacturing feasibility, cost, quality, and brand identity.

When rough sketches, 3-view drawings, and specification notes are provided, the manufacturer can accurately assess the structure, materials, and production methods. This allows for a clear presentation of estimated quotations and production schedules. Conversely, if the design remains vague, the project cannot proceed effectively, leading to significant variances in cost and timeline. Therefore, solidifying the initial design phase is the most important step in creating a high-quality timepiece.

Consult with the Professionals

If you have any questions regarding OEM watch manufacturing or design, please contact “Tokiji,” a professional team specializing in Japanese watches.

Even if you do not have a ready-made design, we can propose a design tailored to your vision through a detailed consultation.